If you want to know how do Floating Staircases work you will be happy to know that there are a number of different ways to achieve the floating stair effect on a staircase. Many types of floating stairs designs are possible and here below you find the ones we recommend.

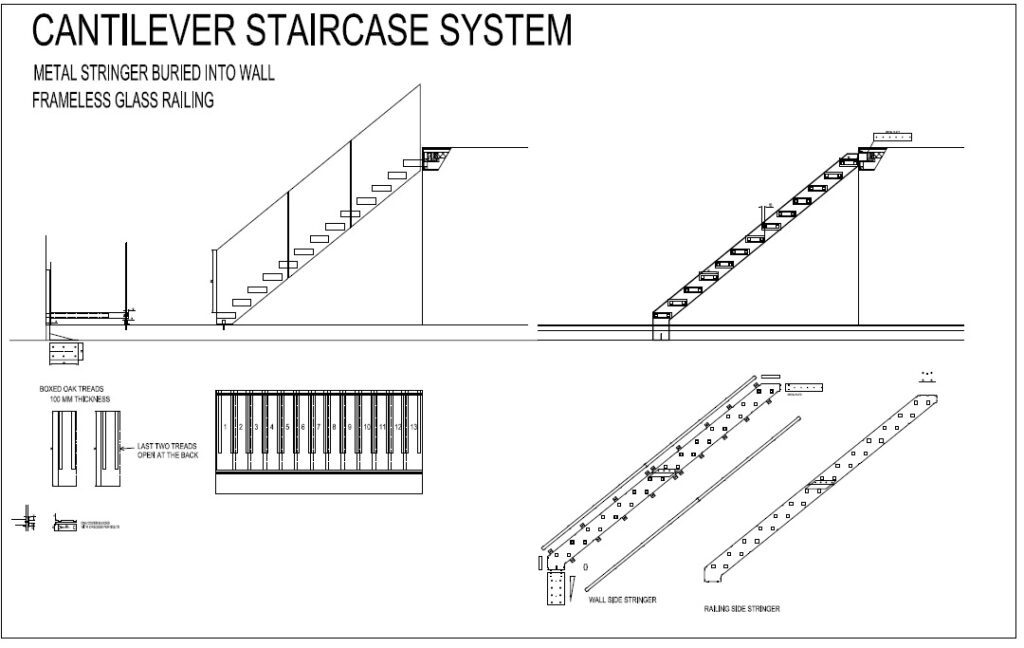

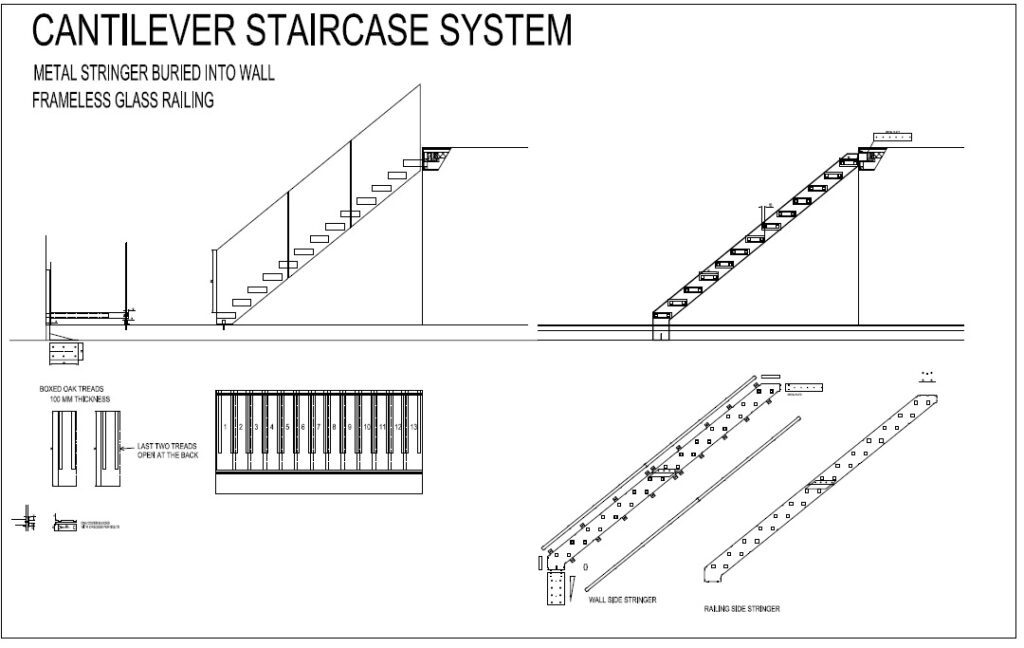

- Hidden Cantilever Stair Stringer – Floating Staircases

- Visible wall stringer on Floating Staircases

- Floating Staircases with Steps fixed directly to wall

- Cantilever Stairways with Structural Glass Walls

- Quasi-floating Stairs or Central Spine Staircases

- Concrete Floating Staircase or resin floating stairs

- Floating Staircases Structural Details

Which is the right cantilever floating treads system for your staircase project?

The first thing you need to check is if you have a wall beside the staircase. Then check if this wall is a self-supporting (load–bearing) wall or not. The floating staircase has to be designed according to this information.

The floating staircase, also known as cantilever staircase or suspended stairway, is nowadays a very popular design. It is especially welcome among Architects and Interior Designers, thanks to its airy, modern and light style.

Despite to its minimalist style, the floating treads have a lot of engineering involved in the design, manufacturing and also installation on site.

Floating Staircases seem to “seamless float” in the air (this is exactly the effect we want to see), but in truth they usually need a strong support system.

Furthermore we can easily plan them to match both modern and classic styles. More Floating stairs ideas are available on our Cantilever Stairs collection.

• Floating Staircases with concealed steel supporting element

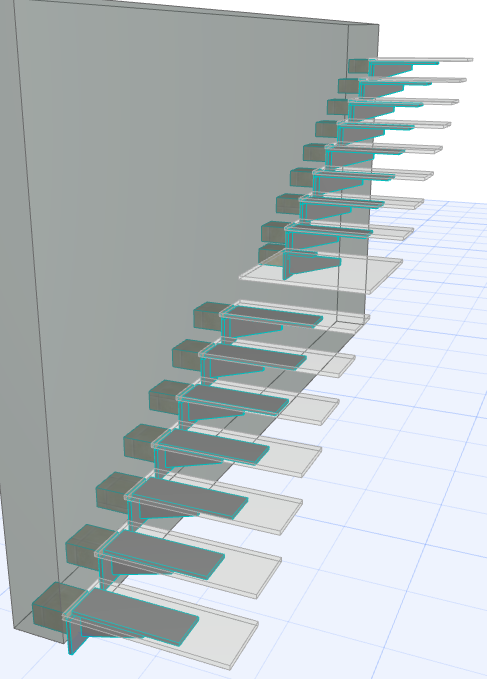

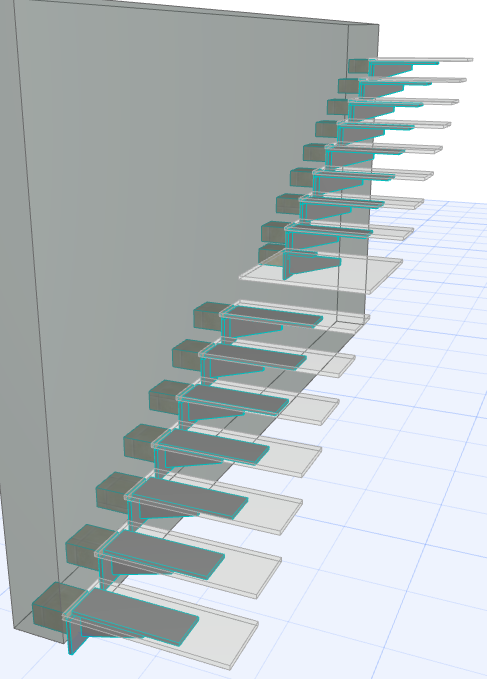

Floating Staircases and self-supporting walls. Hidden Cantilever Stairs stringer or structure.

If there is a wall beside the staircase and it is self-supporting (load-bearing), made of concrete or solid bricks for example, you can plan the staircase with the design you want. We have no structural issues here.

We can manufacture a steel cantilever floating supporting element (stringer) as main support for treads and railing and hide it into the supporting wall. The effect we produce are treads coming our directly from the wall as they were floating into the air.

The railing is possible in many different designs and materials. The most popular is the seamless glass railing with glass panels fixed to side of treads. Fixings can be with stainless steel visible bolts or with wooden covering caps that hide the screws. An external wooden stringer is also a possible option.

Treads are normally made of wood (beech, oak, walnut) and are very thick (80, 90 or even 100 mm). Those measures are required in many countries to comply with building regs. for cantilever staircases with open risers.

The option for thinner treads (50 mm for example) would need closed risers, as riser opening between two treads would be higher than 100 mm.

Beside of wood, an increasing popular tread design is now the resin tread or Corian tread.

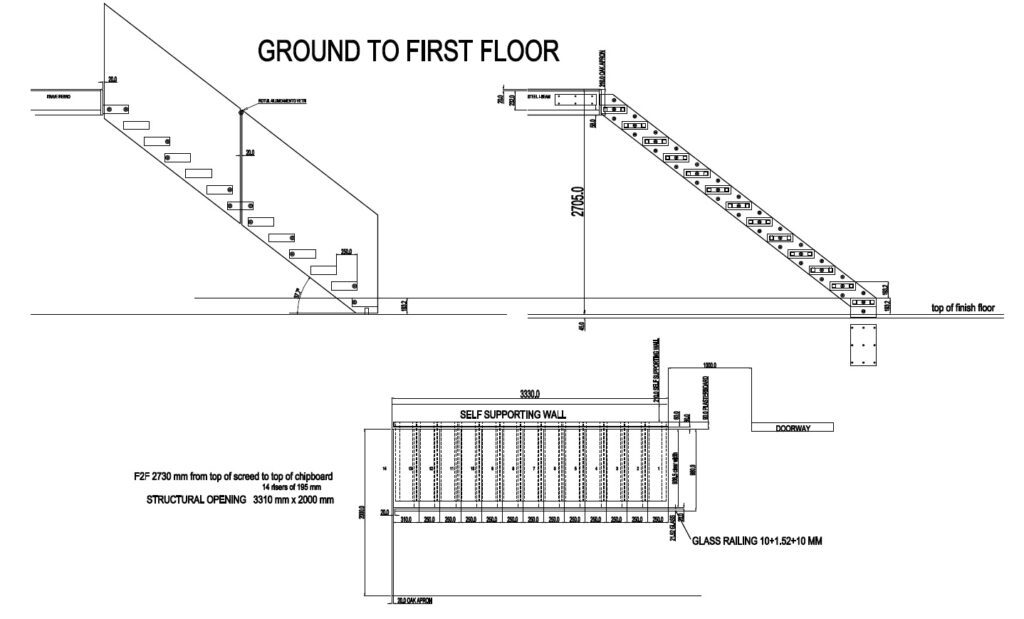

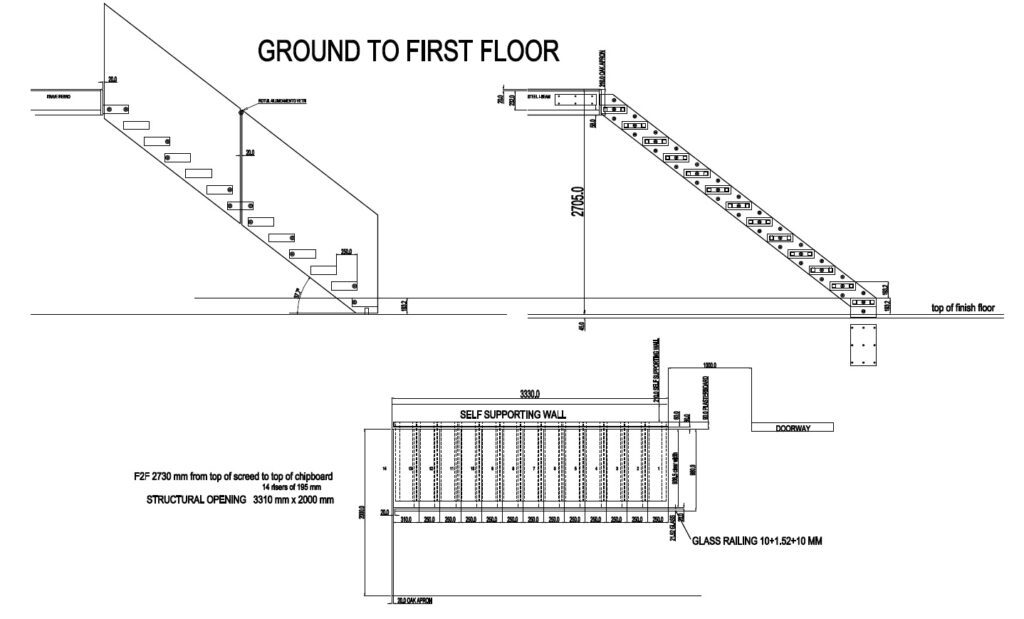

The installation of this fantastic staircase has happened in two different stages. We installed the steel cantilever element first, fixing it to the self-supporting wall using chemical anchor bolts. We fastened it to the floor and to the top slab (or steel I-beam) as well.

Once the cantilever element is properly fitted, builders on site can proceed and finish the wall with plaster, plasterboard or exposed bricks. When the wall is complete you can then install the treads and the railing.

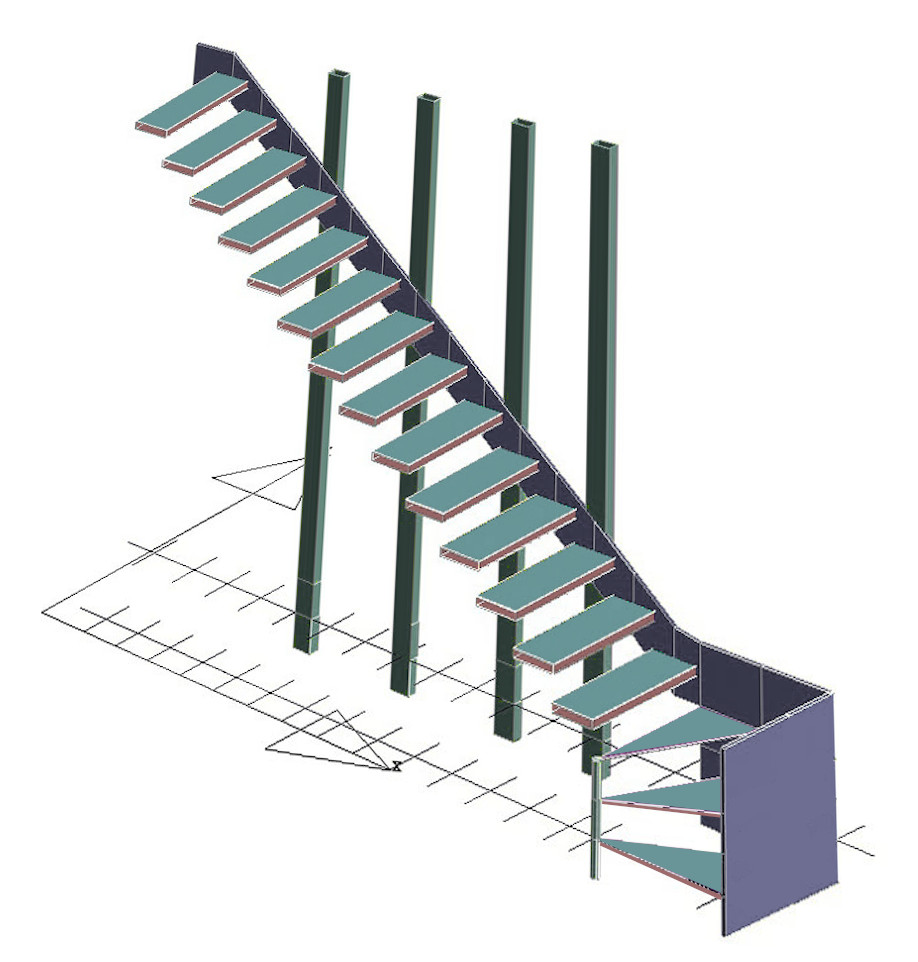

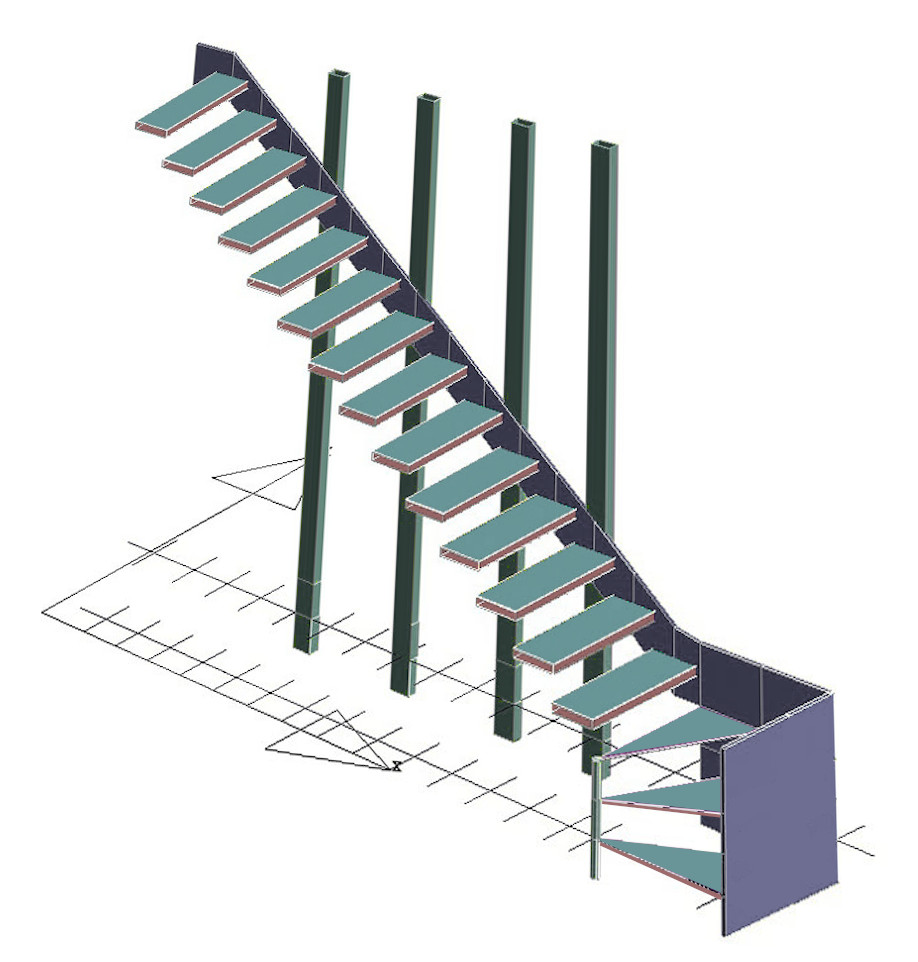

Floating Staircases and non-load-bearing walls

If next to the stairway there is a wall but it is not self-supporting (load-bearing), (as for example stud-walls, partition walls, retaining walls etc.) we cannot fix any cantilever element to it. We have to design alternative solutions here.

How do Floating Staircases work? After having studying all details of the projec, our designers always come out with customized ideas and systems. One possible option could be to have a special strong steel cantilever element with a number of fixing points to the floor and to the ceiling.

Intermediate posts are in this case needed and the cantilever element is more similar to a steel frame structure than a stringer.

After the installation of this steel frame the wall can be finished with plasterboard or other systems. The staircase can therefore be completed and we can install treads and railing.

• Floating Staircases with visible wall stringer. Exposed Stair stringer.

How do Floating Staircases work? This is a very simple system. We can design a laser cut steel stringer and fix it to the wall with no major works outside.

If the wall is load-bearing two or three fixings using chemical anchor bolts are sufficient and no additional fastening points are normally needed. If we have a stud wall instead, we will need to design proper fixing systems. Steel posts to floor maybe needed in this case too. This is not a “real” floating or cantilever staircase but if you paint the steel stringer with the same colour of the wall it will be nearly visible and the floating effect is however present. The steel stringer can be a fascia or have a zig-zag shape (for a lighter design). The railing is possible with any design and material you like. Open or closed risers as different options. Wooden or steel treads are possible.

The installation is here very simple and it normally takes place in one stage only. We do not need in fact to wait masons to finish the wall before fitting cantilever steps. When the wall is finished, plastered (and even painted if you want) we can fasten the steel stringer to floor, wall and ceiling. We fix then treads and railing and everything is done. Fast and easy!

• Floating Staircases with Steps fixed directly to wall

Wall mounted floating stairs

How do Floating Staircases work? In some cases we can design the steps without any supporting steel stringer but fixed directly to a solid wall. This is possible when there are no major structural issues and when the staircase is not too wide (The treads width can be for example 850-900 mm). We fix each single step to wall using chemical anchor bolts and stainless steel spacers between wall and tread. This option is especially good for solid wood treads. In case of open risers we could suggest to add stainless steel spacers among treads to reduce the flexibility on the staircase.

Closed risers and glass railing fixed to floor could in this case help even more to achieve for each tread a more rigid stairway.

The simplest design for floating steps is to use stainless steel bolts fixed to the wall. On the internal side there is usually a glass railing, which helps to give to the whole system the rigidity we need.

Beside the glass balustrade, if you want to have a more traditional or minimalistic interior design, we could suggest the stainless steel hangers from the ceiling. The hangers are usually in stainless steel, but can also be powder coated in any color you want.

In addition to this, there could be a different system we can suggest, as alternative to stainless steel bolts. We can use for each tread stainless steel frames recessed in the wall. The wall has to be solid and cannot be a stud wall or partition wall. The steel or stainless steel frames have rectangular shapes recessed into the wall. They act as support for each single tread. The steel frame is normally visible and can be painted with the same colour of the wall.

We have designed and installed wonderful stairways with this system where the wall connected to the staircase was a featured curved wall.

The staircase is here the leading element of the whole interior design.

• Floating Stairways with Structural Glass Walls

There are projects where no walls are supposed to exist beside the staircase. The stairway for example is the main feature in the center of the room, atrium or lobby. In this case our stairs designers can come out with customized interesting solutions, as for example structural glass walls to support the entire staircase design.

The glass walls are generally on both sides of the staircase and are designed to support the load of each single tread. Treads are often in wood to match flooring or other furniture in the room. To upgrade the floating staircase design we can have them in toughened laminated glass too. This option gives an exclusive touch of lightness and elegance to the whole interior design.

How do Floating Staircases work? Glass walls have to be properly designed to support the entire load of the staircase and they are normally fixed to the floor and/or to the ceiling. We use apposite stainless steel bolts to sturdily fasten the treads to glass walls. We use than stainless steel rails or bolts to have a sound fastening to floor and ceiling as well. Each bolt and fixing is specially design for the load it has to support and this is a guarantee for an authentic structurally sound staircase.

We carefully study all details on a project working with data provided by clients, structural engineers and architects on site. We closely work with them to find out the best customized solution. When needed, we also provide a detailed structural engineering report. We carefully test and design each staircase part according to the specific requirements for the project.

This is especially relevant for commercial staircases, as for examples stairways for shops, restaurants, meeting centers, schools, sport centers and public offices or buildings.

Quasi-floating stairs or central spine staircases

When the structural parts of the building do not allow for installation of a floating or cantilever staircase we have a number of different quasi-floating stairs to suggest. With the quasi-floating stairs system you do not need any floating stair tread brackets. The steel central spine support the treads.

The central spine floating staircase also called mono stringer floating staircase is a very popular choice and allow to have flexible railing designs. We can design the central spine with a minimalist style or a solid look.

Whatever design you chose the quasi-floating stairs with steel central spine will offer a very sturdy but elegant and modern staircase solution.

You can choose again among many different railing styles, from the traditional to the modern glass balustrade. Here below some options for you.

How do Floating Staircases work? This system of quasi floating stairs often allow to have only two staircases fixings, one at departure and another one at exit. If the single staircase flight is long, you may need however an intermediate fixing to a wall.

Many of our clients but also staircases experts use the name floating staircase or cantilever staircase when they refer to staircases with central spine or support as this picture.

This mono stringer staircase is a good solution if you want to have a very strong, rigid and structurally solid staircase. This design is perfect for new build houses but also on remodels and refurbishments. We can fix the central spine to floor and ceiling slab only, with minimal or no support to the walls.

We call this design or style quasi-floating stairs or central spine staircase. You can have straight floating flights but also curved floating staircases. The steel central spine is the main support element for the treads.

Concrete floating staircase or resin floating stairs

One popular design is now the concrete floating staircase.

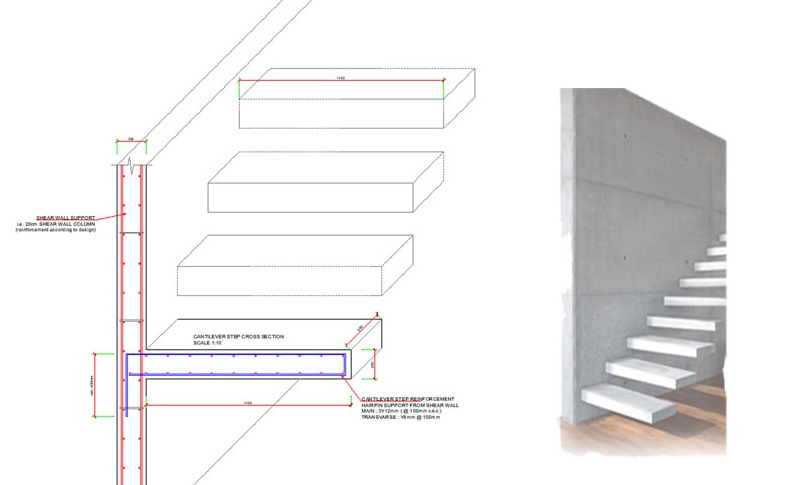

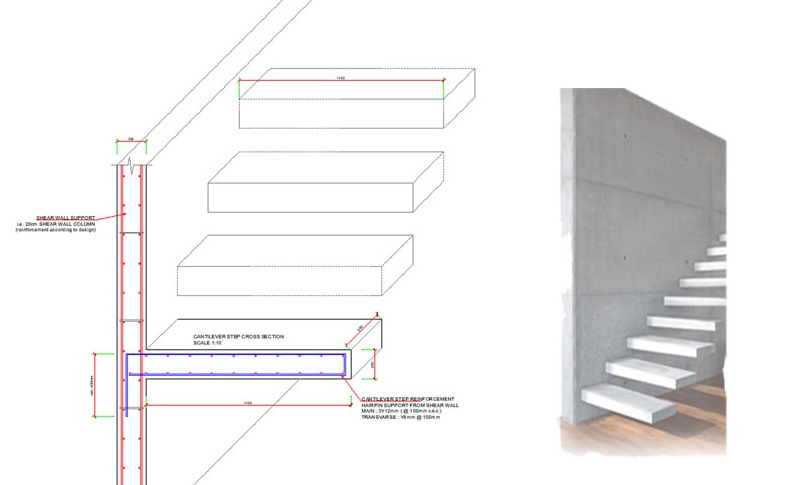

On the Concrete Cantilever Stair Design we can use self supporting floating concrete treads.

The standard tread width can vary from 700 mm to 1300 mm and more, whereas the thickness of the concrete floating tread is from 60 mm to 100 or even 110 mm.

Due to the load of the Concrete floating stairs, we need proper structural calculations both on the supporting wall and on the cantilever concrete steps.

To upgrade the Concrete floating stairs we suggest to add led lights and a modern design glass balustrade.

How do Floating Staircases work? On concrete floating stairs we have a lot of engineering involved and we need to put a lot of expertise when installing the concrete floating stairs. One step only can weight around 120 kg and this makes transport, handling and installation a bit tricky. On the other side, once installed the concrete floating staircase is very very rigid with only a very minimum deflection when jumping on it.

To avoid the problem with the heavy steps we often suggest and supply resin floating staircases or floating treads made of resin. This is a fantastic option if you want to achieve the same look of a stone staircase. You can for example imitate a marble staircase, a granite staircase or any other type of stone you want, including concrete. You will not be able to see the difference between the natural stone treads and the resin treads, both will grant a stunning result.

In addition to the cantilever systems explained in this article we are able to suggest and conceive many other solutions. Each solution is especially studied and designed on purpose for your project.

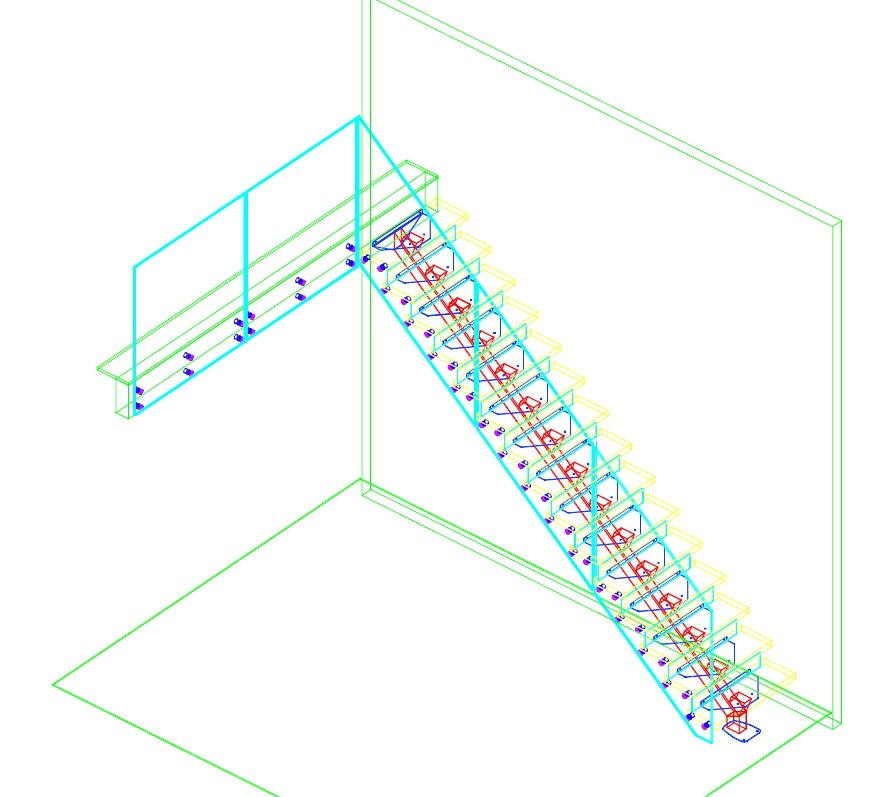

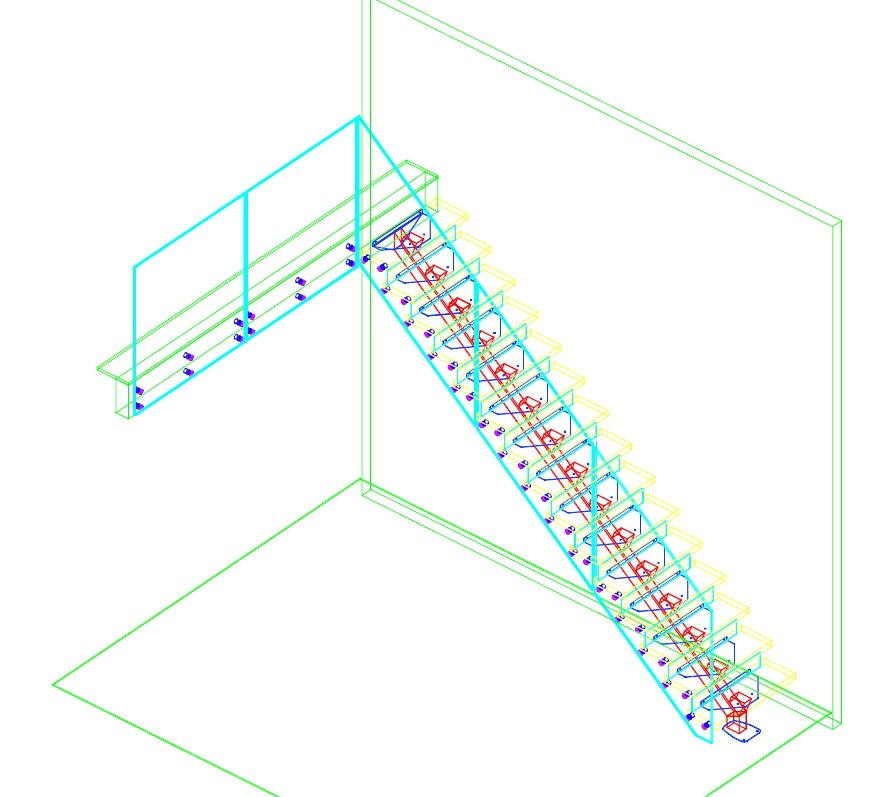

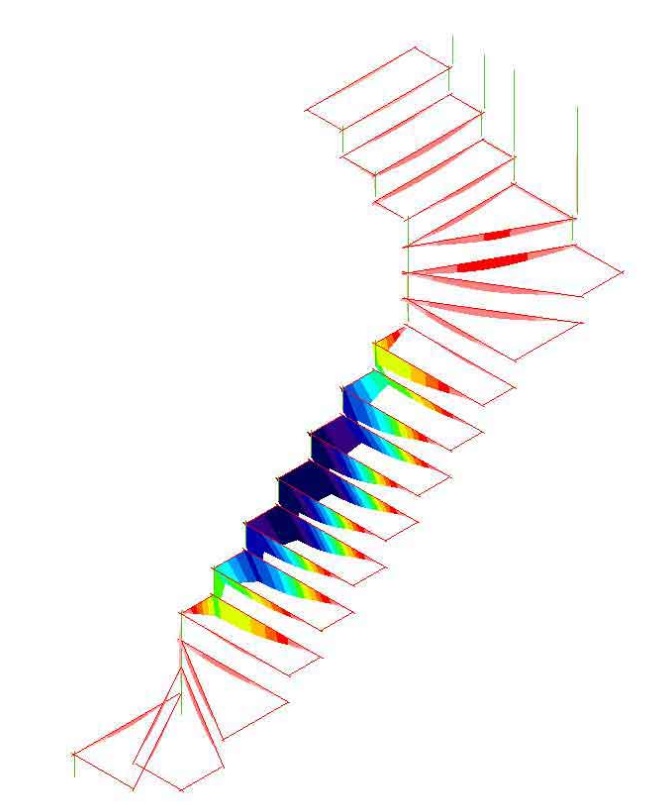

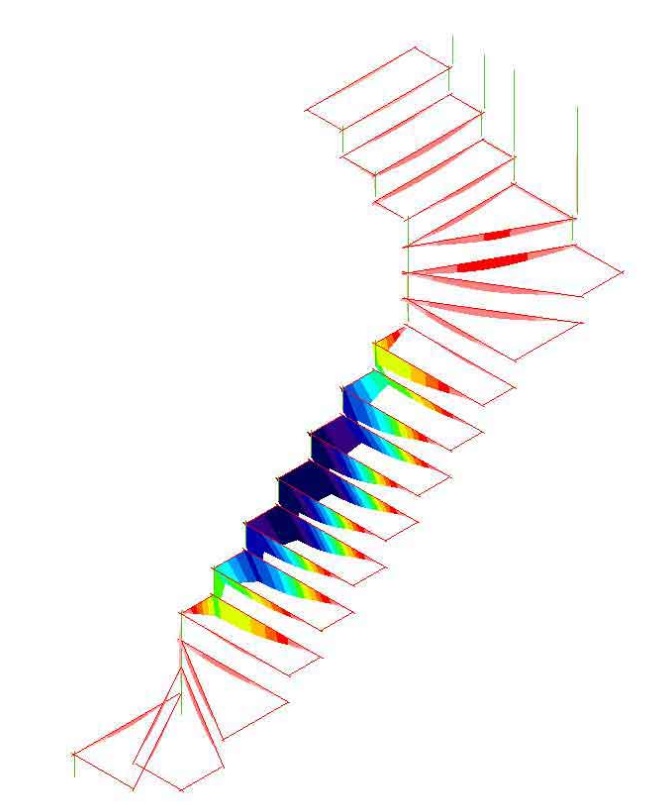

Floating Staircases Structural Details

As previously explained there are a number of different ways to achieve the best Floating Staircase Design.

One important detail you need to check before deciding your Cantilever Staircase Design is your supporting wall.

If it is a reinforced concrete wall with a load capacity for example of 250 kg per step you have no problem. You can install whatever Suspended Staircase Design you want. The railing can be in glass and can have no structural function.

If you have a supporting wall with a load capacity of 100 kg per step you need instead to incorporate the railing as structural part of the staircase. This may be achieve by connecting all treads together by means of spacers that join the upper with the lower step as in this picture.

Now that you know everything on how to design a floating staircase you may wonder what the floating staircase price is. For floating stairs cost take a look at our Floating Staircase Price post.

Do you need more information on how do Floating Staircases work? Do you need more advices to take your final decision on the staircase you want? Are you ready to start your cantilever staircase project with us?

Get started and move on to action …

Floating Staircases Related Articles