Curved Staircases for decks and mezzanines

Modern Curved Staircases give a unique touch of class to any interior design, being this a private house or a commercial place. Here is our guide on how to build Modern Curved Stairs. Curved Staircases are often fitted in the atrium of houses or villas where there is a lot of space available and the curved or helical staircase become the central feature. In houses renovations curved stairs for deck or mezzanine are able to give a dramatic touch of style.

Due to the curved shape, there is a lot of engineering involved in the design of the helical staircase.

The number of steps is given by the floor to floor height (staircase elevation) you have. The minimum width of the staircase is generally 30’ (910 mm) but we can produce curved stairs for a deck up to 70’ or more (2130 mm).

With this curved staircase design guide you will learn how to design (and build) a perfect curved staircase for your deck or mezzanine. Let’s start!

- Step 1. Top tread position.

- Step 2. Number of steps.

- Step 3. Floor to Floor measure.

- Step 4. Landing platform.

- Step 5. Draw the curved staircase plan – Curved or Helical Staircase Design Calculation

- Step 6. Step 6: Check Building Regulations

- Step 7: Curved Staircase styles and design

Step 1. Top tread position

As there is no ceiling opening but a deck, we have no major issues with measures at staircase exit. You only need to check the position where you want the top step to be.

Step 2. Number of steps.

Now that you know where the staircase exit will be, you need to find out where the departure tread will be. There are different system to determine this. The faster way is to allow for a fixed riser height and calculate how many risers (and steps) you need depending on the finished floor to floor you have.

Step 3. Floor to Floor measure. How to build modern curved stairs.

If you have for example a finished floor to floor height of 10’ (3048 mm) you can go for 18 risers of 6 11/16’’ (170 mm) each. On domestic curved staircases we usually have risers value going from 160 to 180 mm. A higher riser could make the staircase less comfortable when climbing up the stairs. However, you should check the allowed value with your local building officer or building codes. The value of risers and going have to be in fact designed according to the stairs building regulations of your area.

The finished floor to floor measure is the vertical distance from top of finished lower floor to top of finished upper floor.

Step 4: Top landing platform.

The top tread is generally designed one riser below floor level and has same measures of all other treads. In some case we can however design the top tread levelled with the floor and bigger than other treads. We call this landing platform.

Step 5: Draw the curved staircase plan – Curved or Helical Staircase Design Calculation

It is quite tricky to draw a curved staircase plan, the good news is that there are many on line staircases calculator that can help you.

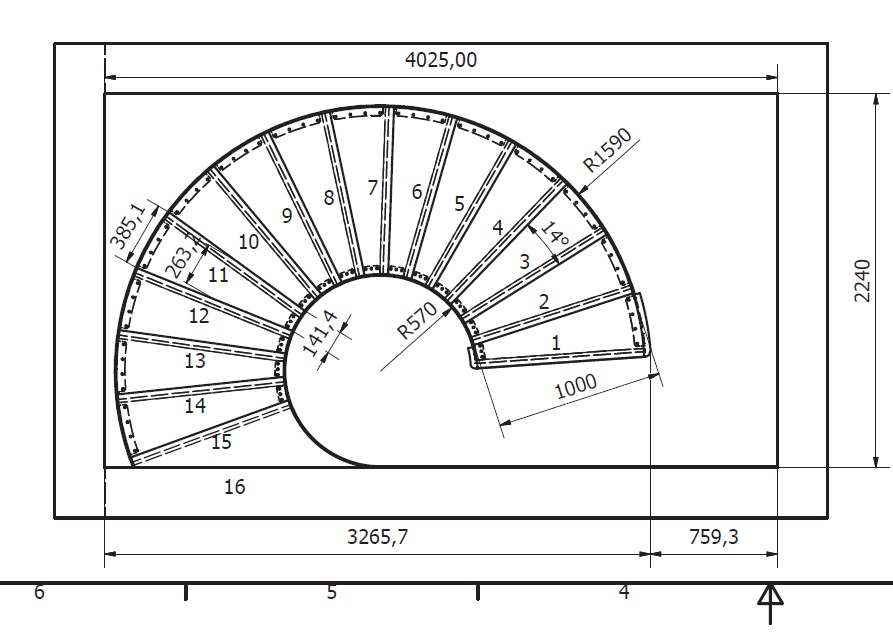

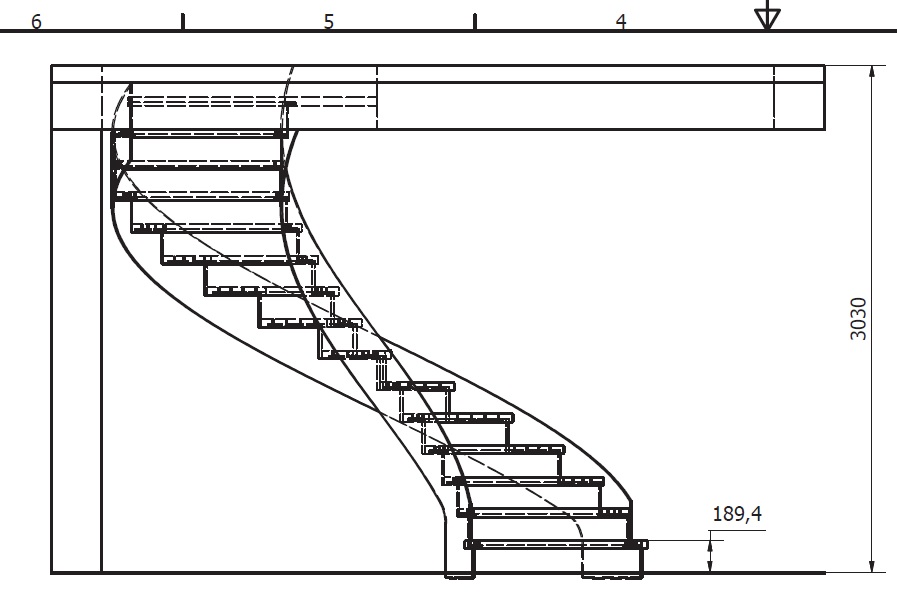

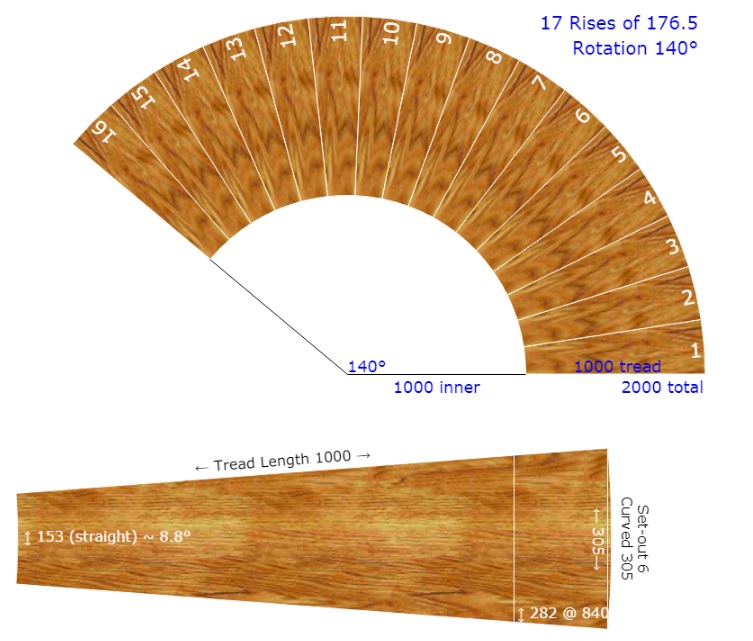

Here below an example of a design for a Curved Staircase for deck.

Staircase: width 1000 mm, floor to floor height 3000 mm, 17 risers of 176 mm, 16 curved steps

Here is how the staircase will look in the curved staircase drawing:

Curved Staircase for deck Outdoor – How to Build modern curved stairs in 7 steps.

The main rules to draw an outdoor curved staircase for deck are similar. There are generally no major impediments or walls, therefore you may be able to design a wide curved staircase to reach the deck.

Being the external staircase exposed to weather conditions you will need to pay attention that all the curved or helical staircase parts are properly treated and suitable for their use. The steel is hot galvanized, the stainless steel is the aisi 316, the wood parts are suitable for external use. For timber external staircase we recommend to use wood types as teak, iroko or any other hard wood not sensitive to humidity, cold and hot temperatures.

Step 6: Check Building Regulations on how to build modern curved stairs.

Check that all measures are complying to the staircases building regulations in your area and you are done! Good Job!

For England and Scotland you can download the complete regulations on the Uk planning portal website.

If you have any doubt on your new curved staircase design, please contact our team today. We will be happy to guide you and suggest the best possible options for your house, sending initial helical stairs’ cad drawings and configurations.

Step 7: Curved Staircase styles and design

Depending on the style and design of the staircase you want to achieve, there are several materials we can use to produce the curved staircase and the curved staircase railing. The materials choice is really vast. If you want a Classic Staircase you can choose among different wood choices as oak, beech, walnut and others. If you prefer instead a Modern Staircase look, you can go for a combination of glass and painted steel or stainless steel staircase. You may also want to lighten up your treads by adding led lights.

The price of the curved staircase for deck will vary depending on the material but also on the staircase engineering. A metal staircase will be the most cost-effective, whereas the glass spiral staircase will be the most expensive. You can also decide for a combination of material, painted steel stringers, wooden treads and curved glass railing. This Curved Glass Staircase option is a high end staircase solution, we can customize it according to any interior design.

Do you need more information on how to build a curved staircase? Do you need further help to take your final decision on the design of your new curved staircase for deck?

Get started and move on to action …