Project Ref.: GDS Stairs Washington -Lloyds Lane, Alexandria VA

Modern Glass Spiral Staircase

If you are looking for a distinctive and unique staircase design for your pool house, summer house or even for your main residence, here is our proposal. Washington Stairs – Alexandria: the most impressive staircase that will give an unforgettable look to your whole house.

Staircase project ref. Washington Stairs – Lloyds Lane Modern Glass spiral staircase

Our spiral staircase with twisted architectural design and premium walnut treads is perfect to achieve a dramatic and elegant design.

- Staircase Project details

- Staircase Project Development

- Staircase Design Features

- Staircase technical data sheet

- Order Process – How it worked

Staircase project details

Type of building: private residence – pool house

Staircase Architectural style: modern staircase

Location: Alexandria, VA – United States of America

Clients testimonial:

Our clients say…

We are thrilled with our custom spiral staircase by Grand Design Stairs. Every detail from the initial design phase to the final delivery was thoughtfully and professionally executed. We love the powder coat finish and colors. Our staircase is stunning, a real architectural work of art.

Thank you Grand Design Stairs for creating something so beautiful.

We really love our stairs and thank you for all your help throughout the project.

Roland & Diana R.

Home owners – Alexandria – Washington DC

Staircase Project Development – Washington Stairs – Alexandria

Roland and Diana, home owners, contacted us when they decided to build a new pool house near their primary home. They loved our spiral staircase design and wanted to receive more information, some design recommendations for their project together with a quote. We contacted their architects to receive drawings with the basic measures we needed. The architects, a custom residential design and architectural firm based in Washington DC, sent us the blueprints, together with information on the interior design they wanted and reference images taken on our spiral staircases website pages to show us the final result they wanted to achieve.

We explored possible options and staircase ideas with the clients on the design, materials and finishes they wanted and then we issued our preliminary study.

Afterward, we sent them our quotation which included the staircases design, production, shipping and installation.

Roland and Diana had a very clear idea of what they wanted: a stunning staircase to impress everyone entering their pool house. They liked the idea of having a white stringer and a twisted centre pole to give an helical shape to the whole staircase design. The curved glass balustrade with wooden handrail was a must to add brightness to the entire pool house.

The premium European Walnut treads, with their amazing peculiar wood grain finishes, were the final touch of class. The clients sent us a floor sample , so we could do our own tests and find the best match for the treads.

We also designed an elegant glass balustrade for the top floor to match the staircase balustrade.

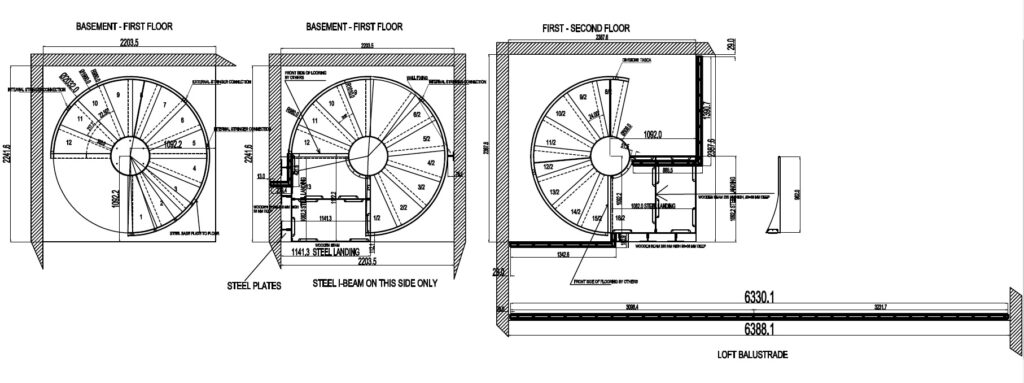

The pool house building frame was originally not designed for two spiral staircases of 6 m in height and 2 m diameter.

Extra structural supports needed

While working with the architects and following the staircases structural calculations provided by our structural engineers, we asked the builders on site to add extra reinforcements to the floors, ceiling slabs and walls. Those extra strengthening elements provided the solid fixings we needed, in order to have a sturdy and rigid solid staircase which could be climbed by all the people living or visiting the house.

We had three technicians and one engineer from Grand Design Stairs team involved in the design process and one interior designer working on materials and finishes.

Once the final design was approved, we sent samples of the materials and colour to the clients and to the architects, so that they could check and confirm that the quality, colors and finishes were meeting their expectations. Everything was approved and we were eventually ready to start production.

With the curved glass involved in the design of both staircases and the engineered twisted center poles, the staircases production took around 10 weeks. We then needed two weeks for the full pre-installation in the factory. We had to pay particularly attention to pre-fitting the curved glass balustrade and the wooden handrail.

Afterwards, the staircases were disassembled and sent to the painting and staining departments.

Once painted, all stair components were double checked before packing and shipping.

Due to the volume, weight and value of the staircases and especially to speed up the shipping process, we decided to book a full dedicated 20’ container to deliver the staircases directly to the site in Alexandria, VA.

The shipping took around 25 days and the staircases could finally reach their new house.

Staircase Design Features

The required design the clients were looking for was challenging. They wanted a real sculptural staircase going from the gym at ground floor up to the second floor. The main challenge was to create a real work of art, but occupying the minimum area possible.

We went for a spiral staircase shape and designed a twisted centre pole to give the wow factor the clients were looking for.

We designed all the staircase fixings to be invisible and this helped to improve the stunning effect we wanted.

Special attention was given to the design of the top landings with an engineered steel frame and steel plates, which had to be solid and structural but gracefully incorporated in the design. The centre pole and stringer were designed to be hidden below the floor level, to achieve the seamless design we wanted.

A special square platform was designed to allow a very comfortable access to the ground floor staircase, a real touch of class to enhance the whole staircase layout.

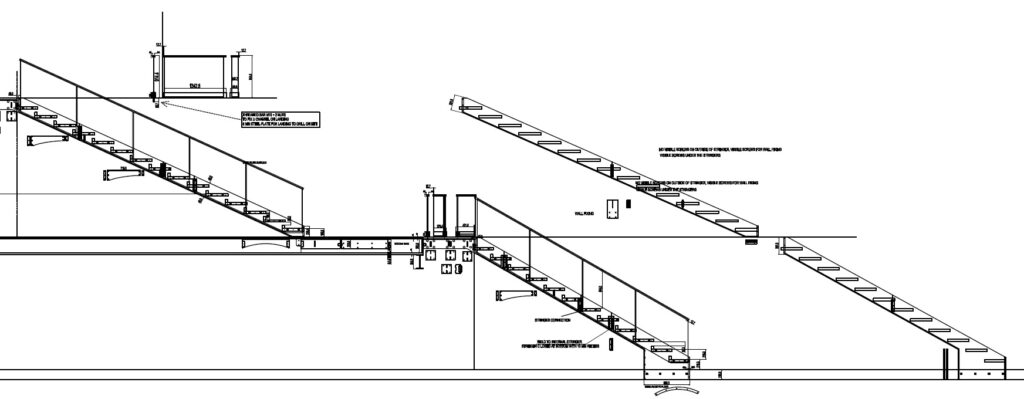

The top floor was a wooden mezzanine with bridge, which we cleverly incorporated into the design by adding a glass balustrade going all along the bridge and matching the staircase railing design, with a white coated channel at the base and a walnut handrail on top of glass, to match both the wood floor and the staircase treads.

Stairs building code

After receiving the information on the local building codes by the architects, we double checked that all components we were designing were fully complying to the required standards. We double checked materials and structural loads. Our structural engineers worked on a Structural Engineering Report and carried out all tests related to the stair design loads required.

All staircase components were designed and produced to be comply with the required codes and rules for spiral residential stairs.

Staircase technical data sheet – Washington Stairs – Alexandria

| Staircase Details | Clients preferred options | Other options & up-grades |

|---|---|---|

| Floor to floor height | 120’’ + 117 3/4’’ | any measure available |

| Ceiling opening | 88 1/4’’ x 86 3/4’’ and 94’’ x 94’’ | any measure available |

| Risers | Walnut up-stands | wooden risers, glass risers |

| Staircase diameter | 6’8’’ | From 4’ to 8’ |

| Staircase stringer and twisted center pole | powder coated steel | stainless steel |

| Staircase Treads and up-stands | oak | beech, iroko, walnut |

| Railing model | Curved glass with wooden handrail | Stainless steel or powder coated with rods or full height panels |

| Top Floor landing balustrades | Top mounted glass balustrade with white channel | side mounted glass balustrade with aprons |

| Steel staircase parts finishes | powder coated matt white | White, light grey, dark grey, rust effect or stainless steel |

| Wooden staircase elements | Solid European Walnut stained to client’s sample floor | beech, iroko, walnut smooth or brushed in different wood stains |

| Additional items | LED lights on treads |

Order Process – How it worked – Washington Stairs – Alexandria

Step 1– staircase details – Washington Stairs – Alexandria

The architects sent us an email inquiry for some technical details on custom spiral staircases and asked us to study and review the initial plan they had issued for a double-story spiral staircase.

We gave our suggestions to better accommodate the staircase into the pool house, using all the space we had available to make sure the staircase was comfortable to climb, but stunning to see.

We worked on different layouts and achieved the final one which was approved by both the architects and the customers. Being a two-story spiral staircase, the entrance and exit points were limited to certain areas. We also had to follow geometric rules for circular staircases and, of course, pay attention to the building regulations requirements.

It was not an easy task but we came out with a design that satisfied everyone: customers, architects, builders and building inspectors.

The center pole was originally designed by the architects to be in curved glass. This was not technically possible due to the small radius needed and the engineering involved in bending the glass. For this reason, we came up with the custom steel twisted centre pole design, which was a great solution.

The walnut treads stained to match the wooden floor gave an extra touch of class to the entire staircase design.

Walnut is a very exclusive and expensive wood type with unique grain features and incomparable beauty.

Step 2 – staircase quote

We sent our initial quote to the customers and they came back asking for some upgrades.

The original quote was with stainless steel handrail and rods, but the customers wanted a more impressive design and we suggested the curved glass.

We discussed some further improvements, such as how to sandwich the glass into stringers with invisible fixings, rather than side bolted to the stringers. We added a spectacular round handrail fitted on top of glass and the customer was happy to proceed and place the order.

Step 3 – Staircase Concept Design – Washington Stairs – Alexandria

One of the main features of this spiral staircase is the seamless design. Clients and architects wanted all fixings to be invisible, no joints or screws.

We had to amend the initial drawings a few times to stick to the changes that builders were making on site. We sent our drawings and recommendation on how to design and build the structural elements in the building, needed to support the staircase load.

The original slabs were in fact not strong enough and we sent to the architects and structural engineers our information on how to build them to be solid rock. We carefully designed the stairways according to the staircase code requirements received from the structural engineers regarding the loads on handrails and guardrails and the loads on stairs.

As a main requirement from the architects, we also had to stick to the applicable code for staircases issued by the City of Washington.

Step 4 – Staircase Production drawings

Our technicians and engineers reviewed the initial drawings. Then issued the shop drawings in an AutoCAD file, ready to be submitted to the customer, architects and building regulations inspectors for their final approval. They were approved, and we could start the staircases production.

Step 5 – Staircase Construction – Washington Stairs – Alexandria

We started the staircase construction by working with the curved steel stringers on a special laser-cutting machine. Afterwards we produced the twisted center pole too. At the same time, our carpentry division was creating the wooden treads and risers stairs parts and the curved walnut handrail.

We created the curved glass railing and preinstalled it on the stringer, checking all single fixing points and carefully testing that the glass was according to our quality standards.

We had to remake two wooden steps, as they had slight imperfections on the surface and re-install them.

Our team pre-fitted the walnut wooden handrail on top of the glass and everything was perfect, ready to be stained and finished.

Step 6 – Staircase shipment

We disassembled the staircases, checked each part and packed everything for the shipment.

We booked a 20’ container to load the wooden crates, prepared all shipping documents and everything was ready to be despatch to Alexandria – Virginia, USA. The shipping by sea took 25 days and 7 days for customs clearance.

Step 7 – Staircase Installation

Once the shipping company delivered the staircases to site, we liaised with the installation team to give them diagrams, instructions, tricks and tips on how to carry out the installation in the best way. Some lifting tools were needed on site to lift the heavy center poles, stringers and, of course, curved glass panels.

The team was very efficient, working pretty fast and cleverly. One issue came out when installing the bottom panel of the curved glass railing which initially cannot be aligned with the top glass panel. The glass railings can sometimes be tricky and installers on site are often worried about breaking the panels. Our engineers suggested a simple solution, which was to use provisional wooden spacers between two glass panels to tighten and align them. The solution worked and the installation was completed.

The last items to be installed were the glass landing balustrades and the glass guardrail on the bridge.

That’s it! Everything done and a magnificent 2-story staircase finally there to enhance the luxury and elegance of the pool house, ready to receive appreciation from the family owners and their guests.

Get started with your staircase project …