A cost-effective wooden staircase may cost around $3,000.00, whereas the most expensive wooden staircase can reach an amount of $70,000.00 and over.

The price of a wooden staircase mainly depends on three factors:

The most cost-effective wood specie is the fir whereas the most expensive is the walnut.Spiral Stairs are generally cheaper than half-turn or curved stairways.

On bespoke stairs there is always a lot of engineering involved both in the design and manufacturing process. Stairs designed and produced using CNC machines are normally cheaper than handcrafted staircases. With the CNC machine the production process is highly automated and stairs parts can be manufactured in big quantities reducing production times. For this reason Staircases manufacture with a CNC machine are generally cheaper.

In this article you find useful information on wood stairs prices and an explanation of how the three above factors may affect the final price, as well as some details on wood certification, quality and maintenance.

1-Wood species

We produce staircases in many different wood species. Here below you find a list of wood selections which are among the most popular species used in modern interior design. Those species are also the most suitable for staircases production.

Please be aware that not all wood or timber choices are appropriate for staircases. We need to be very careful as a bad choice with the wood species or wood quality may compromise the whole staircase rigidity and structural soundness.

The best choice is always the solid wood, rather than manufactured wood as plywood, mdf, veneered, engineered or others. We may decide to use however multilayer woods in some particular cases, when for example a special engineering on treads is required.

- Fir wood: this is a soft wood and the cheapest wood we can recommend to build a staircase.

- Beech wood: Beech is a hard, strong and quite heavy. It has a fine, tight grain and veins. Beech wood is light in colour and has pretty good resistance to scratches. It is a popular wood for staircases and furniture in general. It is quite easy to work and you can obtain a even finish just with a soft sanding. If you are looking for good quality at a reasonable price, the choice of a beech staircase could be the right one for you. Its light colour makes it also easy to stain and you can therefore have the treads and risers matching any other furniture or floor in the house.

- Oak wood: Oak is each day more and more required by Interior Designers and Architects. It is highly appreciated thanks to the beautiful wood grains and veins. It has good wearing properties and is quite heavy. The lack of oak wood as raw material makes it a quite expensive choice. Depending on the dimensions of stairs parts the price of oak can be from 30% up to 45% higher than beech. This is the reason why you may decide to choose a beech staircase stained to oak, rather than a solid oak staircase.

- Walnut wood: this is one of the most expensive wood type we recommend for staircases. Walnut is a hard wood and is recognized for its strength, nice veins and its chocolate brown colour. There are however many different walnut species coming from different countries. The range of colors and grains is always different The walnut species we suggest are the European or the American Walnut. The walnut price is also different for each type, it is however always more expensive than oak.

- Wenge wood: Wenge is an African timber with a uniform dark brown chocolate color. It is often used on laminate flooring. We sometimes use solid wenge on stairs to match the flooring. Wenge can have a very uniform color and straight grain. It is a good wood for furniture, cabinets and of course staircases too. Thanks to its unique dark color, this exotic wood can give a dramatic look to your interior design. The Wenge trees (called Millettia laurentii) are listed as “endangered” as the existing population is decreasing rapidly. For this reason the cost of wenge timber as raw material is high. The final price of a wenge staircase is consequently higher than other wood as beech or fir . If you really like the wenge color but need a cost-effective staircase solution, we recommend the solid beech stairway stained to wenge.

2-Staircase shapes and designs

Spiral Stairs

Beech Spiral Staircases are in our opinion the most cost effective hardwood solution. We can supply spiral stairways entirely manufactured in beech or as a combination with other materials as stainless steel or powder coated steel (for a even more economic option). All beech components (treads, risers, railing and center post) can be natural varnished or stained to different shades.

The most popular choices are beech stained to light or dark walnut and beech stained to oak or to wenge. All-beech spiral staircases are popular in Northern Countries and where a traditional interior design is required.

Oak spiral staircases are also a good choice. If you want to have a really stunning all-oak staircase we suggest the twisted spiral staircase. The center post is twisted and the railing manufactured with a lateral fascia wrapping all around the staircase.

If you really like walnut or wenge wood but cannot afford to have an entire staircase made of those wood species we suggest to have treads in solid wenge and center post and railing in powder coated steel.

Straight Stairs

Straight stairs are often used as utility stairs and are usually not the main staircase in the house. If this is your case you should think to have a fir wood staircase.

If you need instead a straight staircase as main feature in your house we suggest a beech or oak staircase with open or closed risers.

You could also decide to fill the space under the stairs with a storage closet or a book case made to measure with the same wood type.

An indicative price for a beech straight staircase vary from $3,000.00 to $6,000.00

Cantilever Staircases

A very popular design for straight stairs is the floating staircase. It usually has chunky wood treads coming out from the wall and glass railing. No visible staircase support structure. To meet building regs treads can be manufactured to be 90 or 100 mm thick to avoid closed risers or riser bars. A special engineering is here needed and treads are normally manufactured using multilayer wood.

This special manufacturing and the type of wood needed generally bring to a quite high price. We can also manufacture floating stairways or Cantilever stairs with solid wood treads 50 mm thick and wooden closed risers.

L-shape/Quarter Turn Staircases

When planning the staircase we usually calculate how many treads and risers are needed and we can possibly find out that a straight staircase is not feasible. To have an acceptable slope for the staircase we may need to add more risers and treads, even if the space we have for the staircase is limited. In this case we design a L-shape or Quarter turn staircase with the turn placed at the bottom or at the top.

This design is more expensive than the straight staircase as we need more treads including winders (kite shaped treads used to reach the desired the turn). An indicative price for a quarter turn staircase entirely manufactured in beech is from $3,500.00 to $6,800.00.

U-shape/Half Turn Staircases

The half-turn also named U-shape staircase is an alternative to the quarter turn staircase. It consists of two straight flights connected by a 180 degrees turn. We can achieve the turn using six winders at 30 degrees, four winders at 45 degrees, two square landings or one rectangular landing. The choice depends on how many risers and treads you need to reach the floor to floor height you have.

The cost of winders, square or rectangular landing is normally higher than straight treads. For this reason U-shape Staircases are also more expensive than straight flights.

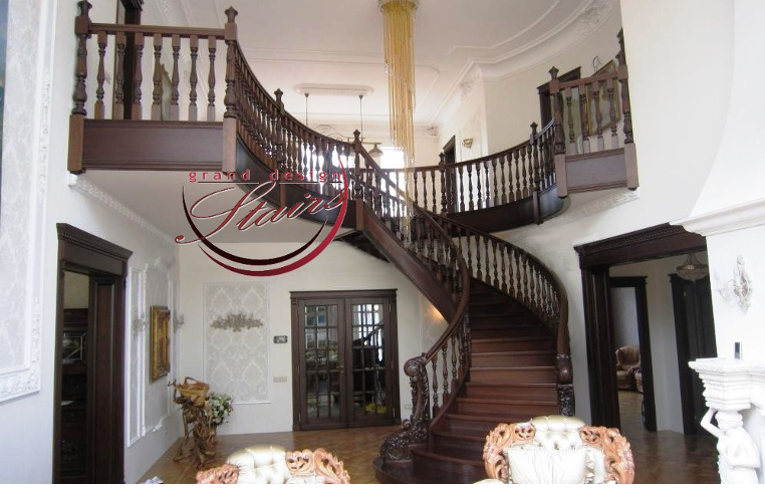

Curved or Helical Stairs

The elegance and the splendor of the wood find here the best application. If you are looking for a really stunning and prestige staircase take a look at the following picture and give us your opinion. This masterpiece of elegance and distinction was carefully handcrafted piece by piece, screw by screw.

The curved stringers have been designed to wrap all around the staircase from the first featured tread to the top of the staircase. The splendid curved landing balustrade at first floor complete this stunning wood masterpiece.

The featured wooden newel posts at staircase entrance have been entirely carved by hand for a unit cost of $2,500.00. The final price of this stunning curved staircase can exceed $100,000.00.

Curved stairs can be designed with straight treads at the entrance or stair exit instead of all curved treads. This option reduces the final price considerably. If you can build a curved wall on one side of the stair we can avoid the second railing and this reduces the cost even more.

Outdoor stairs

Do you need an outdoor staircase to connect your garden to the first floor of your house? Do you need a secondary access to a balcony or terrace ? Would you like to have it in wood? Then, please read following recommendations.

Take the utmost attention in choosing the right wood as only few wood species are suitable of external use. The wood itself as raw material is sensitive to humidity and extreme weather conditions.

The best wood species for outdoor staircases are the teak and the iroko.

- Teak is the strongest and most durable among the hardwoods. It is highly used in the construction of boats and yachts but also in furniture for gardens and urban design. It contains a natural substance that acts as water repellent and makes its surface safe from warping and cracking. Even with low maintenance a staircase made of teak lasts hundreds of years. It may be treated with oil or sealer to improve its natural durability.

- Iroko is another durable hardwood. The wood color is initially yellow but darkens to a richer reddish brown over time. As happens with Teak, Iroko is also used in ship and boat building and also exterior furniture. Thanks to its properties it is often used as a structural timber too. In the interior design it is used on parquet flooring, decking and of course staircases. While having very good durability in wet and extreme weather conditions the price of Iroko compared to teak is much lower, this is because as raw material it is available in greater quantities.

3- Engineering involved in the stairs manufacturing process

Wood Stairs manufactured with CNC technology

While there is a big audience that still prefers fully handcrafted stairs the staircase production with CNC technology is becoming more and more popular. The pioneers in conceiving the first stairs design software were very few German companies more than 30 years ago. The software was directly connected to a CNC machine for staircase production were very few German companies more than 30 years ago.

From that time the technology has continuously evolved and today there are several softwares available that can design stairs in a simple and intuitive way, giving essential and rapid execution commands to CNC machines.

The Wood Stairs manufactured with CNC technology took in some way advantages from this development.

As often happens, the greater selection of softwares and CNC machinery available on the market allowed to have lower prices on final products. The price of CNC wood stairs is therefore nowadays more affordable than in the past.

CNC Wood Stairs have standard features and designs, which can be however customized by adding some luxury items as led lights and glass infill. Led lights can be placed on treads, handrail and even on stringers. Glass panels can be used on staircase railing as infill under the wooden handrail or as closed risers among treads.

Handcrafted Wood Stairs

The skills and expertise of our designers and craftsmen go beyond all limits here. We can design staircases for any application.

From the simplest domestic stair design to the most luxury staircase project for private villas or luxury hotels.

Each stair part is carefully manufactured, sanded, polished and oiled or stained by hands. Particular attention has to be brought to curved wood parts as stringers, fascias and handrails. A special engineering is needed here to shape the wood to the required curved design.

All stairs components are pre-fitted in the factory, the curved parts are molded directly on the staircase to ensure the optimal fitting once delivered to site.

Commercial Wood Stairs

Wood commercial stairs have the special feature to enhance the interior design of the atrium or foyer where they are normally fitted. Wood commercial Stairs are always elegant and can match any style being this traditional or modern.

The building regulations for commercial or public staircases normally require an increased treads width as those stairs are generally used by many people at the same time. The dimensions of the commercial wood staircase make it even more elegant and awesome. The best wood species for those stairs are oak and iroko.

Wood Certificates and Quality

To ensure the optimal structural soundness and quality of our staircases we only use FSC certified wood (Forest Stewardship Council). This is our assurance that the wood comes from FSC certified forests.

This means in particular that we carefully check the origin of wood as raw material and also pay attention to how it has been handled and stored before reaching our premises.

Wood species coming from non-FSC certified suppliers are in general of much lower quality. Since controls are only occasional, when present they may contain wood worms or insects that can wear the wood out very fast.

The FSC certificate is a guarantee of top quality product and generally it does involve an increase in the final price of the finished product.

Regarding the wood or timber quality, we only use first grade materials. Wood is in this case free of imperfections and knots as they may compromise the integrity and rigidity of the staircase. Stairs built with 2nd or 3rd grade quality timber may be found on the market at very cheap prices. If you are thinking of buying one of those, we recommend you carefully check if they are suitable and strong enough for the use you need. You can also ask to the supplier to have structural calculations and further guarantees.

Cleaning of Wood Stairs

Fir Wood, Beech Oak and Walnut: all brand new wooden staircases normally need to be cleaned by removing the dust only. They do not need any additional care.

This is valid if the wooden staircase has previously been stained, varnished or oiled in the factory just after manufacturing completion. The varnish, stain or oil in fact act as protector against humidity, spots and scratches too.

You just need to remove the dust from the stairs with a cloth. If you want, you can then clean the stairway with a humid cloth and water, then dry it with a clean and dry cloth. That’s it! All done!

Maintenance of Wood Stairs

After some time, maybe years, you may want to re-fresh the natural beauty of your staircase. The wood in fact being a porous material can change shades with time. You can then apply another coat of varnish or oil to the neat surface. You can find many products specific for wood or stairs maintenance that are available on diy shops at reasonable prices.

If the staircase has a lot of heavy traffic, as on commercial or public stairs for example, the finish on wood stairs might worn out or crack after some time. In those case a heavier maintenance is needed and you may need to apply for a professional repairs service. The stairs have to be probably sanded with proper tools to remove the oil or varnish. This before being varnished or oiled again. Ask for quotes to different professionals for a competitive maintenance service as cost may vary depending on the job and on expertise of the professionals involved.

Teak and Iroko: as previously explained, Teak and Iroko are very strong and long-lasting timbers. They only need some basic cleaning to remove dirt, which can be done with a humid cloth. Use a little amount of soapy water if needed. In diy shops or also marine tools shops you can find a number of different good Teak and Iroko cleaners. Once applied they will clean and brighten the timber at the same time. For an even thorough maintenance you can then decide to apply a specific sealer specific for teak or iroko. The wonderful honey brown teak color or yellow/reddish brown will be enhanced even more.

Do you need more information on wood stairs and their costs? Then do not hesitate…